Manufacturing process

Extensive experience and competence in Technical Ceramics combined with our highly qualified and motivated team and efficient state-of-the-art manufacturing techniques ensure your and our competitive advantage.

We use leading edge CAD and CAM systems for CNC machine programming.

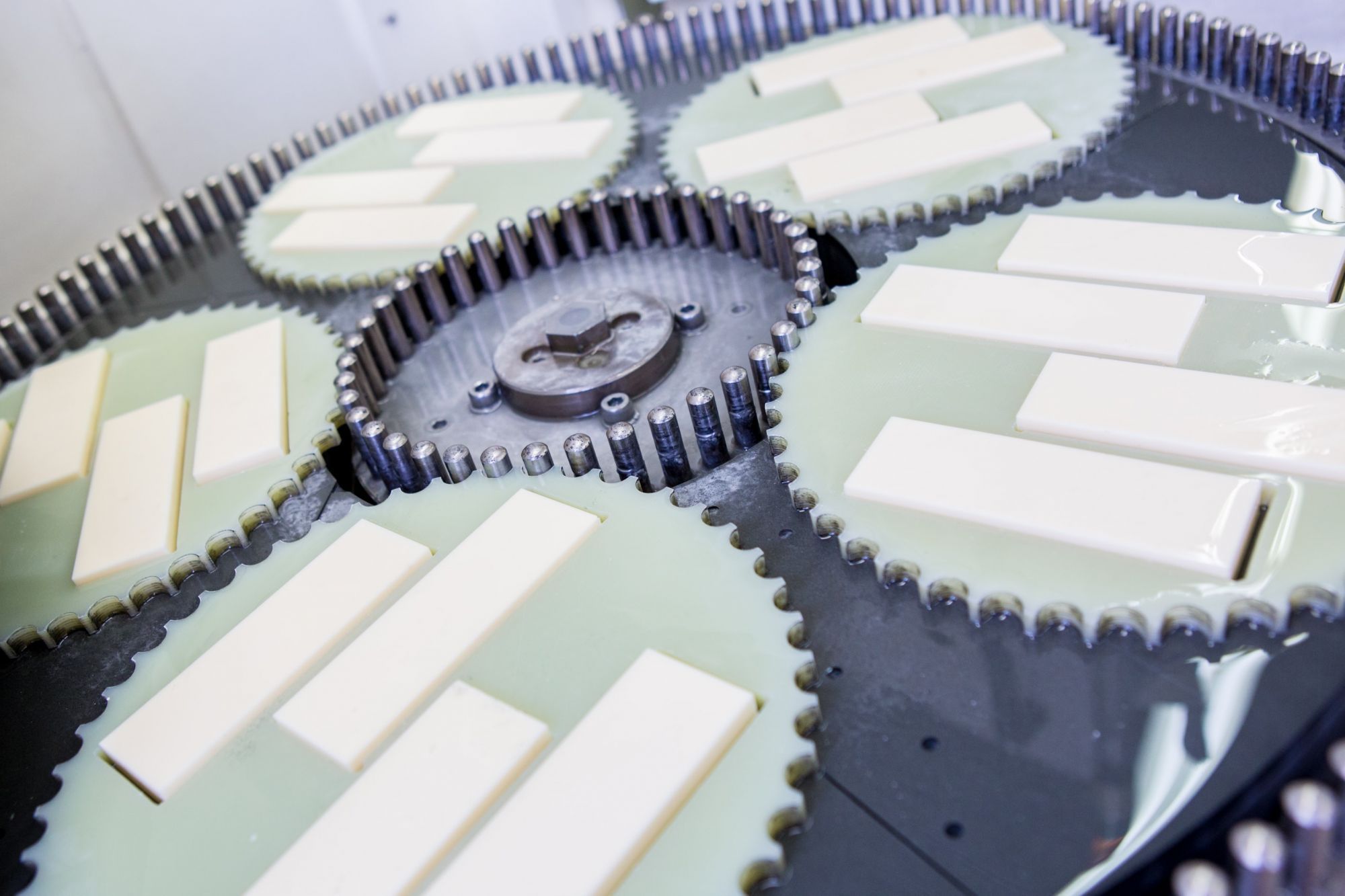

- CNC surface grinding

- CNC external and internal grinding

- CNC coordinate grinding

- CNC profile grinding

- CNC thread grinding

- Double-side surface grinding and flat honing

- Centerless grinding

- Honing

- Flat lapping

- Flat polishing

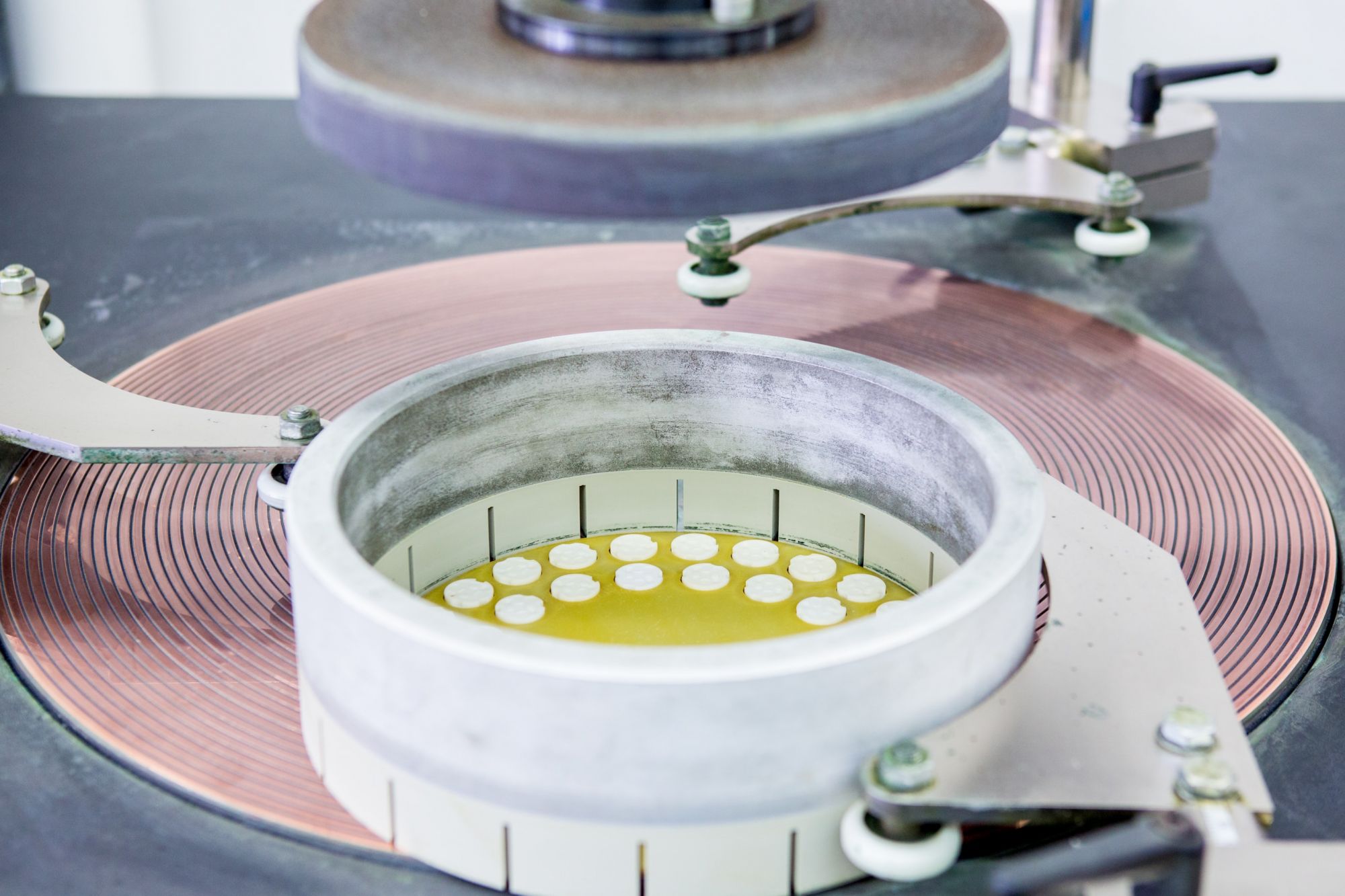

- Cylindrical lapping

- Cylindrical polishing

- Slide grinding

- Ultrasound machining

Each year, we invest in modern and economic production equipment and continuous staff training.

We use state-of-the-art CNC machines to manufacture sophisticated high-precision technical ceramic components on a 2,000-m² production site.

Double-side grinding

CNC cylindrical lapping

CNC surface grinding

Honing

CNC grinding

Advanced manufacturing standards for more than 30 years